SYSTEM AMADA

SYSTEM AMADA OVERVIEW - PRESS BRAKE TOOL

European Precision Style/promecam is the most common system in the world which and used on press brakes like Adira, Amada, Baykal, Boschert, Bystronic, Colgar, Dener Makina, Deratech, Durma, Ermaksan, Energy Mission, Gasparini, HACO (Atlantic), Harsle, Hindustan Hydraulics, MVD, Nargesa, Salvagnini, Schiavi, Yangli, YSD etc.

All European Precision Style press brake tooling is manufactured from Chrome Based Alloy Tool steel with an induction heat treated for added durability.

Our European Precision Style tooling comprises a diversity of punches, dies and accessories. Available in segmented, full-length and half-length sizes to fit any metal bending applications.

We are able to assist the customer to recommend tools according to his parts as well as to prepare the sequence for the special shapes if necessary.

PUNCHES

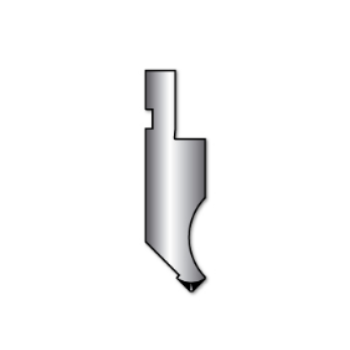

Acute Punch

Sharp punches are available at angles from 26 to 60 degrees. These are also widely used for the first operation in hemming.

Gooseneck Punch

Gooseneck punches are ideal for forming special shapes like deep profile, channel forming & U Profiles in two strokes. Such punches are designed to allow for large return flanges in the workpiece. The gooseneck shape compromises the strength of the punch so it can’t handle quite the same tonnage as a standard punch.

Straight Punch

The straight, narrow punch body enables flanges to wrap around both sides for bending symmetrical profiles. Straight punches are more suitable for closed profiles.

Sash Punch

which are thin tools that are straight along their entire length. Ideal for use in tight spaces, they are designed to perform final bends on a part where there is very little clearance left (such as closing up a box nearly all the way).

Standard Punch

It is low profile, semi-gooseneck punch that is perfect for bending 90-degree angles. More strength so it can handle more tonnage. Best suitable for continued usage.

DIES

SINGLE “V” Die

Single Vee dies are the most used, as their name suggests they possess a single ‘V’ shaped groove of varying angles with the minimum distance from the middle of the vee to the back of the tool to allow the minimum joggle available without crushing the tool.

SINGLE “V” Pillar

Single V Pillar dies are available with an angle range from 30 to 90 degrees, V openings from 6mm to 25mm and heights of 80mm or 120mm.

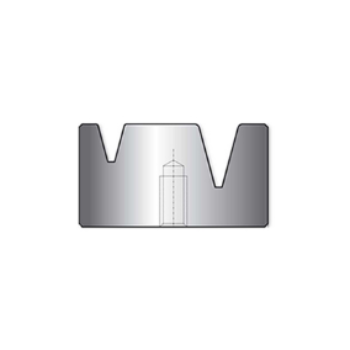

2V Bolted

2V Bolted dies boost efficiency with two precise openings on the same die. Obtainable with angles ranging from 30 to 90 degrees and V openings from 4mm to 25mm.

2V Self Centering

Two-way Self-Centering Vee Dies have two successive grooves (typically of differing angles and/or widths) which give the operator the convenient potential of working continually without any need for retooling if your workpiece has different bend requirements. Additionally, with two grooves they are much closer to the sides of the die making shorter flanges a possibility.

Multi V DIes

Multiple openings can be machined into a single steel bar. 4-way press brake dies and die holders are typically used to replace single-vee dies and can significantly reduce die-change time.

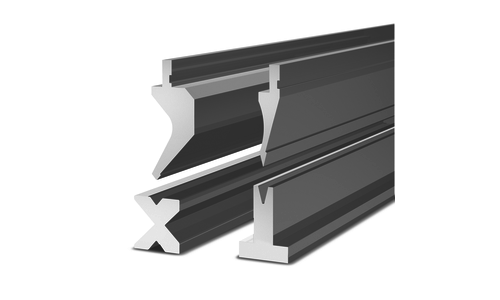

Self Centering Die Rail

2V Self-Centering die holders let you extend the precise height. Two main die styles quick-change 1V and quick-change 2V provide alignment-free changeover and no need for an extra step to secure the die.

Die Inserts

Die inserts are available in angles of 30 or 90 degrees with V openings between 4mm to 25mm.

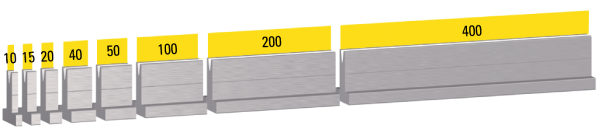

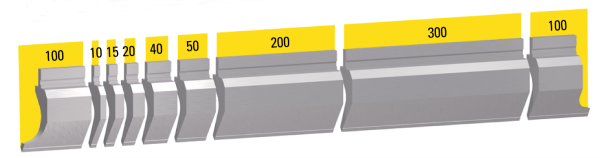

TOOL LENGTHS

PUNCHES/TOP TOOLS

Length 835 mm

Length 415 mm

Length 835 mm sectionalized

The sectionalized punches or top tools are provided as an entire set

9 specific segments and horn extension positioned left and right.

DIES

Length 835 mm

Length 415 mm